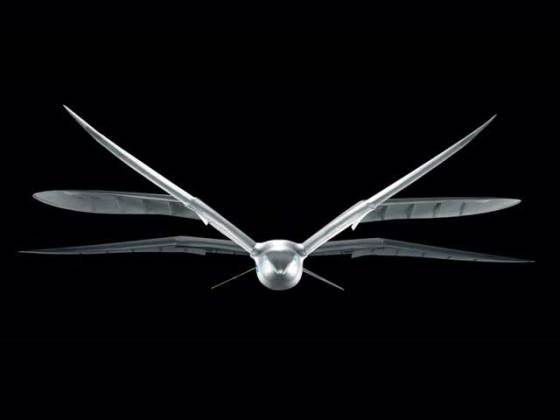

Festo SmartBird mechanical bird inspired by herring gull

Inspired by the herring gull flight, the engineers of Festo’s Bionic Learning Network came up with SmartBird – an ultralight but powerful flight model with excellent aerodynamic qualities and extreme agility. It is capable to take off autonomously and lift-up in the air by means of its flapping wings alone, without the aid of other devices to provide lift.

Inspired by the herring gull flight, the engineers of Festo’s Bionic Learning Network came up with SmartBird – an ultralight but powerful flight model with excellent aerodynamic qualities and extreme agility. It is capable to take off autonomously and lift-up in the air by means of its flapping wings alone, without the aid of other devices to provide lift.

SmartBird has a total weight of 485 grams (a bit over a pound) and a wingspan of 2 meters (6.5 feet). Its wings not only beat up and down, but also twist at specific angles. This is made possible by an active articulated torsional drive, which in conjunction with a complex control system makes for unprecedented efficiency in flight operation. Propulsion and lift are achieved solely by the flapping of the wings and have a power requirement of only 25 watts.

Flapping-wing flight comprises two principal movements. First, the wings beat up and down, whereby a lever mechanism causes the degree of deflection to increase from the torso to the wing tip. Second, the wing twists in a way that directs its leading edge upwards during the upward stroke, so that the wing adopts a positive angle of attack. If the rotation were solely due to the wing’s elasticity, it would result with passive torsion. On the other hand, if the sequencing of the torsion and its magnitude are controlled by an actuator, the wing’s torsion is active.

SmartBird’s wings consist of a two-part arm wing spar with an axle bearing located on the torso – a trapezoidal joint as is used in enlarged form on industrial excavators – and a hand wing spar. The trapezoidal joint has an amplitude ratio of 1:3. The arm wing generates lift, and the hand wing beyond the trapezoidal joint provides propulsion. Both the spars of the inner and the outer wing are torsion-resistant. The active torsion is achieved by a servomotor at the end of the outer wing which twists the wing against the spar via the outmost rib of the wing.

When SmartBird lifts its wings, the servo motor for active torsion twists the tips of the hand wings to a positive angle of attack, which is then changed to a negative angle a fraction of a wing beat period. The angle of torsion remains constant between these phases. Thanks to this sequence of movements, the airflow along the wing profile can be optimally used to generate thrust.

In order to control the flight, a microcontroller calculates the optimal setting of two servo motors, which adjust the torsion of each wing. The battery, engine and transmission, the crank mechanism and the control and regulation electronics are housed in SmartBird’s torso. A two-stage helical transmission of the exterior rotor motor causes the wings to beat up and down with a reduction ratio of 1:45. This motor is fitted with three Hall sensors that precisely register the wing’s position. Both the flapping and bending forces are conveyed from the transmission to the hand wing via a flexible link. The smooth flight is ensured by the crank mechanism has no dead centre and thus runs evenly with minimal peak loads.

The opposing movement of the head and torso sections in any spatial direction is synchronized by means of two electric motors and cables, thus making SmartBird highly agile and maneuverable. The tail of SmartBird also produces lift, because it functions as both a pitch elevator and a yaw rudder, and it can aid in turning left or right.

Since the active joint torsion drive requires precise coordination between the flapping and twisting movements, it is subjected to continuous all-round monitoring. The wing’s position and torsion are monitored by two-way radio communication with ZigBee Protocol, which transfers information such as battery charge, power consumption and input by the pilot. In addition, the torsion control parameters can be adjusted and thus optimized in real time during flight. Along with the electronic control system, this intelligent monitoring enables the mechanism to adapt to new situations within a fraction of a second.

The applications of coupled drives for linear and rotary movement range from generators that derive energy from water – so-called stroke wing generators – to new actuators in process automation. The folks from Festo have already used biomimicry to develop similar products in the past, but the focus of this research is on energy-efficiency and conservation of resources.

As usual from Festo, very interesting.

author

You can watch a new video of Festo SmartBird being presented at TED:

http://www.youtube.com/watch?v=Fg_JcKSHUtQ