Candle soot used to create superamphiphobic glass nanostructures

Although we already wrote about many materials that could serve as liquid repellant surfaces, the one developed by researchers at the Max Planck Institute for Polymer Research in Mainz and the Technical University Darmstadt stands out by being superamphiphobic. They used candle soot to produce a fluorinated silicon coated silica nanostructure which is capable to repel both oil and water.

Although we already wrote about many materials that could serve as liquid repellant surfaces, the one developed by researchers at the Max Planck Institute for Polymer Research in Mainz and the Technical University Darmstadt stands out by being superamphiphobic. They used candle soot to produce a fluorinated silicon coated silica nanostructure which is capable to repel both oil and water.

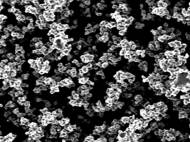

While fluorinated silicon compound already makes the surface water and oil repellent, the innovative part of this research is in the structure of the coating. The soot from a candle flame served as inspiration for a glass imprint of a sponge-like labyrinth of unordered sphere-shaped pores.

In order to create the surface, the researchers held a glass slide in a flame so that the soot particles (which measure only 40 nanometers in diameter) formed a sponge-like structure on the glass. Vapor depositing of a volatile organic silicon compound and ammonia onto the soot deposit fills the space around the soot particles. After the material gets heated, the soot decomposes and leaves the sponge-like surface which is exposed to vaporized fluorinated silicon which coats it.

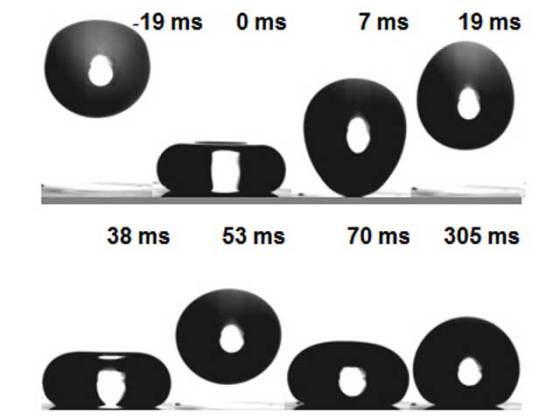

The researchers performed experiments where they tried to wet this coated surface with a total of seven liquids and found that none was sucked up by the glass sponge. Even when they let cetane drip from a great height onto the surface, the end result was the repelled drop on the surface. Although a part of the initial oil drop managed to penetrate into the sponge-like structure, once it bounced back and fell from a lower height, the drop drew the small amount of the cetane that had remained out of the glass pores.

The experiments showed that the material is superamphiphobic because even if a portion of the layer was removed the glass structure remained repellant from any side. This property is ensured because its internal structure is the same as its structure on the surface. It only loses its self-cleaning properties when the layer becomes thinner than one micrometer.

Unfortunately, tests in which the researchers let sand trickle onto the delicate glass structure made the coating wear away quite quickly.

“In a next step, we would therefore like to develop a layer that is superamphiphobic, with better mechanical stability”, said Doris Vollmer, who heads a research group at the Max Planck Institute for Polymer Research.

Once it is perfected, the coating could find its use as a water and dirt repellant surface for a wide variety of products with glass such as lenses in glasses, windows, and car windscreens. It could also be used to prevent residues of blood or contaminated liquids on medical equipment.

For more information, read the article published in the journal Science Express named: “Transformation of black candle soot into a transparent robust superamphiphobic coating”

Nothing lost when the candle burns!

Dr.A.Jagadeesh Nellore (AP),India

E-mail: anumakonda.jagadeesh@gmail.com