Packaging made from tomato by-product waste

Researchers working on the project BIOCOPAC (“Development of bio-based coating from tomato processing wastes intended for metal packaging”) have devised a new range of alternative bio-based lacquers for application on the outside and inside of tinplate cans using tomato by-product waste. This innovative, eco-friendly packaging will decrease waste, improve metal can quality and reduce use of plastic containers.

Researchers working on the project BIOCOPAC (“Development of bio-based coating from tomato processing wastes intended for metal packaging”) have devised a new range of alternative bio-based lacquers for application on the outside and inside of tinplate cans using tomato by-product waste. This innovative, eco-friendly packaging will decrease waste, improve metal can quality and reduce use of plastic containers.

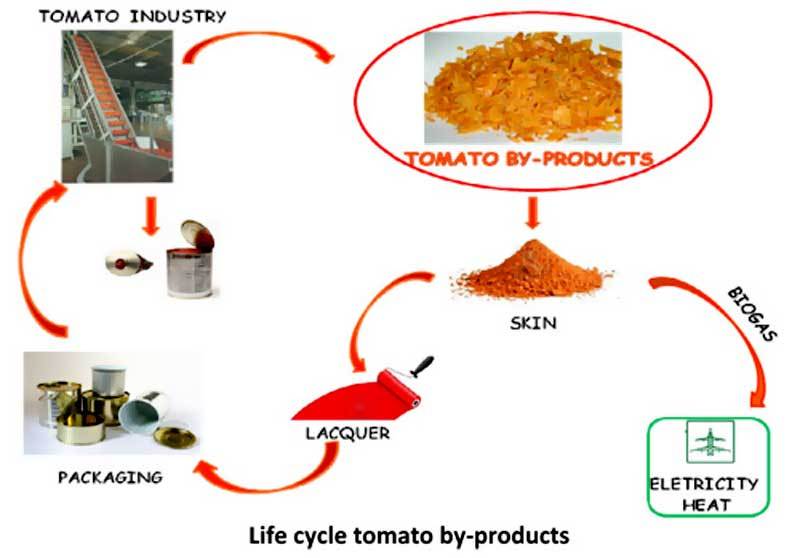

Most of the cultivated tomatoes are processed into foods, such as ketchup, pasta sauce and canned goods. During processing, up to 40 percent of the tomatoes end up as residue, mainly skin, pulp and seeds. If this waste is not used, it increases the disposal problem and environmental pollution.

Led by the Experimental Station for the Food Preserving Industry (SSICA) in Italy, the BIOCOPAC consortium has used processing by-products in the tomato industry to create bio-based thermosetting lacquer for the metal packaging used for food products. The main component of these new lacquers is a biopolymer bio-resin extracted from the cuticle of the fruit. The bio-resin is actually cutin – a wax-like water-repellent biopolymer found in the walls of various plant cells.

The research team has used environmentally friendly techniques to extract cutin from tomato peels. Extracted cutin is then processed into an eco-friendly varnish for food-contact application. This natural lacquer has chemico-physical properties similar to currently used materials in food industry. It is designed to meet European Union legislation requirements and additional tests confirmed the suitability of the new lacquers for food tins and packaging. Packaging containing this lacquer safeguards consumer health and is recyclable.

This project has the potential to inspire new research for other bio-based products that could utilize other waste by-products with novel methods. Ultimately, the research could lead to improved use of Europe’s renewable agri-food resources and support companies with a goal to become more environmentally sustainable.

Small and medium enterprises (SMEs) could benefit from this approach. For example, CHIESA (an innovative bio-refinery) and MARTINETE (a tomato preserving industry company) have jointly filed a patent application regarding an innovative extraction method for cutin separation and extraction from tomato processing waste.

The BIOCOPAC consortium is looking forward to scale-up the technology into a pilot plant. They are also interested in establishing cooperation with partners in order to bring their idea onto the market.

Excellent.

Dr.A.Jagadeesh Nellore(AP),India