Team Maryland WaterShed wins the Solar Decathlon 2011 (part 1)

U.S. Department of Energy Solar Decathlon 2011 ended last weekend and the team coming from the University of Maryland which dominated most of the categories and won the overall first place with their WaterShed house. The team also won the second place after the Middlebury College in the final juried contest – Market Appeal – which was announced just before the overall winner.

U.S. Department of Energy Solar Decathlon 2011 ended last weekend and the team coming from the University of Maryland which dominated most of the categories and won the overall first place with their WaterShed house. The team also won the second place after the Middlebury College in the final juried contest – Market Appeal – which was announced just before the overall winner.

During the competition, groups of experts judged the competing entries in ten categories: their architectural qualities, market appeal, engineering, educational/communication effort, “comfort zone”, hot water systems, appliances, home entertainment, energy balance, and affordability. The category we mentioned last was introduced this year, and it represents an important role in balance and commercialization of these projects.

The Team Maryland involved students and faculty from the Maryland School of Architecture, Planning and Preservation, the A. James Clark School of Engineering, the College of Computer, Mathematical, and Natural Sciences, the University Libraries, and the School of Agriculture and Natural Resources. Maryland businesses and professional groups provided significant support as well.

“These students from diverse disciplines effectively formed a cohesive team to imagine, invent, and make real the project we call WaterShed”, said Amy Gardner, project’s principal investigator and an associate professor of architecture at the University Maryland. “Interdisciplinary problem solving is the way forward towards a more sustainable future.”

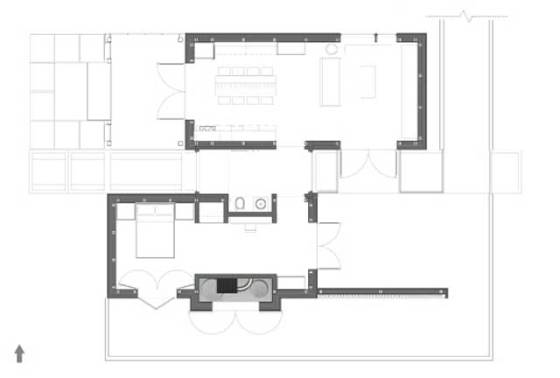

WaterShed house has nearly 83.6 square meters (900 square feet) of conditioned space, and two large outdoor decks. Three interior volumes consist of two larger “shed” modules and a connecting bathroom space. The framing of WaterShed was completed at ProBuilt, a modular home building factory. Its efficient, cost-effective, durable and time-tested structural system along with technological solutions used to achieve high efficiency performance in an affordable manner, helped it beat the competition.

The framing allows application of continuous rigid foam insulation over the house exterior, and its 10cm (4 inch) thickness dramatically reduces ‘thermal bridging’. Additional open-cell spray foam insulation in the wall cavities and closed-cell foam in the roof and floor bring the total insulation value to R-40+ in the walls and R-50 in the roof and floor cavities.

To provide moisture protection, WaterShed is sealed with a liquid-applied membrane air and moisture barrier from Tremco. This system self-heals when penetrated and shrinks and expands with changes in temperature. Having an advanced air barrier allows WaterShed’s heating and air-conditioning systems to maintain efficiency, saving energy and money.

The exterior of the house features two species of locally manufactured, thermo-treated wood. Thermo-treated wood doesn’t require chemicals in order to provides properties associated with pressure-treated lumber. Instead, the wood is “cooked” at high temperatures over a period of time, making it resistant to rot and insects, and rendering it dimensionally stable as well. The thermo-treated woods are treated with a waterborne sealant. Heister House Millworks provided thermo-treated poplar siding and a ventilated rain-screen help ensure no water vapor gets trapped in the walls.

Inside the home, WaterShed features several environmentally conscious finishes from tile with recycled content to low-VOC paints. Unique engineered lumber flooring, Bellagio Microline provided by Oregon Lumber Company, is constructed with a rapidly renewable wood core and backing systems and contain no VOCs.

The ceramic tile on the floor and shower walls in the bathroom module is composed of 40% pre-consumer recycled content. This tile, manufactured by Emil Ceramica, a leader in recycled product material, is laid in random running bond and appears to extend out into the wetlands on either side of the bathroom. Crafted by Luke Works, the sleek custom-made concrete countertops in both the bathroom and the kitchen are composed of approximately 70% recycled content.

Although we tend to publish our articles on a single page, due to the length of this article we’re splitting it in two parts. The second part will be published on Wednesday.

Looks very warm while being balanced and efficient!

Can’t wait for the other part of the story. Why did you split it? T_T

author

The article would have been too long if I didn’t.

You won’t regret waiting for the second part.

In the last Solar Decathlon in D.C ., all the Local and National TV and Radio Stations were silent ! Not a word the first day ! All along the Mall were only International TV and Radio stations, and almost none from the USA, what a shame! EVERY ROOF OF EVERY BUILDING LOOKING UP TO THE SUN AND THE WIND!, and we need practical products for exports.