Where art and technology meet – Solar-Sinter

After a while, we’re publishing an article in our art and technology series, where we write about usage of technology to preserve or create art. Industrial designer Markus Kayser used the solar power and sand as raw energy and material to produce glass objects using a 3D printing process, that combines natural energy and material with high-tech production technology.

After a while, we’re publishing an article in our art and technology series, where we write about usage of technology to preserve or create art. Industrial designer Markus Kayser used the solar power and sand as raw energy and material to produce glass objects using a 3D printing process, that combines natural energy and material with high-tech production technology.

“In August 2010 I took my first solar machine – the Sun-Cutter – to the Egyptian desert in a suitcase. This was a solar-powered, semi-automated low-tech laser cutter, that used the power of the sun to drive it and directly harnessed its rays through a glass ball lens to ‘laser’ cut 2D components using a cam-guided system”, said Kayser. “The Sun-Cutter produced components in thin plywood with an aesthetic quality that was a curious hybrid of machine-made and “nature craft” due to the crudeness of its mechanism and cutting beam optics, alongside variations in solar intensity due to weather fluctuations.”

The experience of working in the desert with the Sun-Cutter led him to the idea of a new machine that could be used to transform sand into glass. When heated to melting point and allowed to cool, silicia sand solidifies as glass. This process of converting a powdery substance via a heating process into a solid form is known as sintering – a central process in rapid prototyping known as 3D printing or SLS (selective laser sintering).

As we mentioned in our previous articles, 3D printers use some sort of heat source such as lasers in order to create 3D objects from a variety of materials such as powdered plastics, resins and metals. By using the sun’s rays instead of a laser and sand instead of resins, Kayser came up with an idea of an entirely new solar-powered machine and production process for making glass objects.

“My first manually-operated solar-sintering machine was tested in February 2011 in the Moroccan desert with encouraging results that led to the development of the current larger and fully-automated computer driven version – the Solar-Sinter”, said Kayser. “The Solar-Sinter was completed in mid-May and later that month I took this experimental machine to the Sahara desert near Siwa, Egypt, for a two week testing period.”

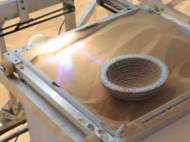

Solar-Sinter has two photovoltaic panels which power servos and the mechanism that tracks the sun, while the power used to cut wood and melt sand is realized only by sunlight concentrated through a large Fresnel lens. The lens focuses the sun’s rays to a focal point onto a platform holding the silica sand and when one layer is completed, the platform drops down to allow for the sintering of the next layer. The process repeats until the object is completed.

Although it is not precise or effective as some of the other 3D printing technologies available, Kayser used this experiment to raise questions about the future of manufacturing and potential further development of manufacturing in the desert.

Good innovation to adopt solar energy.

Dr.A.Jagadeesh Nellore(AP),India

Wind Energy Expert

E-mail: anumakonda.jagadeesh@gmail.com