More efficient and cell-free production of biomolecules

Scientists and engineers from eight Fraunhofer Institutes have joined forces in an interdisciplinary research project to develop bioreactors that produce proteins without the help of intact cells. It can also function without viable, genetically modified cells or organisms. This cell-free bioproduction could help produce biological ingredients more quickly and with fewer resources than current conventional techniques.

Scientists and engineers from eight Fraunhofer Institutes have joined forces in an interdisciplinary research project to develop bioreactors that produce proteins without the help of intact cells. It can also function without viable, genetically modified cells or organisms. This cell-free bioproduction could help produce biological ingredients more quickly and with fewer resources than current conventional techniques.

Many substances can already be produced on a large scale using biotechnology. Currently, biomolecules are often produced using living cells or organisms. This involves adding the gene that codes the target protein to bacteria, yeasts, or cultures of animal or plant cells.

These modified organisms are then cultivated in bioreactors before the protein is finally isolated and purified. There is no doubt that the mentioned approach is very effective, but it does have disadvantages, as many of the steps in the process are costly and time-consuming.

What’s more, the bacteria and other cells themselves consume part of the resources to stay alive, thus reducing the efficiency of the protein synthesis process. Also, many proteins such as membrane and toxic proteins cannot be produced in cells or the results are very poor.

Cell-free techniques do not suffer from these problems, because instead of employing living cells they take only those cell elements needed for protein synthesis. Researchers must break down the cells to obtain a mixture known as a lysate, which contains all the necessary elements for protein synthesis. Alongside enzymes, this also includes biologically active organelles and membrane parts that synthesize the proteins according to their genetic coding. The desired genes can be added straight to the lysate.

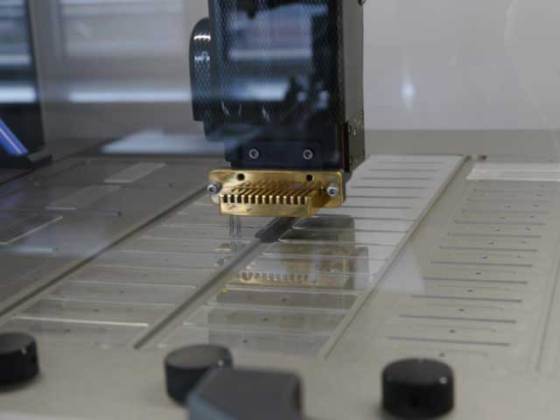

The joint Fraunhofer research project led by Frank Fabian Bier, professor at Fraunhofer Institute for Biomedical Engineering (Fraunhofer IBMT), seeks to adapt the technique for industrial production. The first stage was the development of automated cell harvesting and extraction techniques to produce lysates from bacteria, tobacco, and insect cells. A completely automated process supplies these lysates with amino acids and selected genetic material so that the synthesis of specific proteins can start.

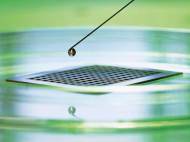

There are two concepts that are currently being tested for use in industry. One idea consists of small synthesis chambers with a partially permeable membrane. Ingredients for the reaction can be fed to the lysate through the membrane, while removing harmful metabolites. A supply and disposal system of this kind allows protein synthesis to keep going for several days.

The other idea includes a microfluidic platform on which the reading of the genes and actual protein synthesis occur in separate places in a way it does in animals and plants. This system is particularly suited to lysates from animal and plant cells.

The Fraunhofer IBMT research team has already produced various proteins including membrane proteins with cell-free technology. The cell free production of membrane proteins has great potential for new kinds of biochip-based activity assays and screening systems for pharmacology.

“There is still a lot of scope to improve cell-free systems, and they show huge potential for making the large-scale production of important biomolecules far more economical and sparing with resources than ever before”, said Bier.

Leave your response!