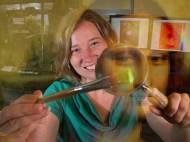

Creating Mini Mona Lisa image with 30 microns in width

A team of researchers at the Georgia Institute of Technology (Georgia Tech) has recreated the Mona Lisa, one of the most famous paintings, on the smallest canvas. They painted the “Mini Lisa” on a substrate surface which measures just 30 microns in width or one-third the width of a human hair. The team was able to vary the surface concentration of molecules on such short-length scale, thus enabling the use of this technique to achieve nanomanufacturing of devices.

A team of researchers at the Georgia Institute of Technology (Georgia Tech) has recreated the Mona Lisa, one of the most famous paintings, on the smallest canvas. They painted the “Mini Lisa” on a substrate surface which measures just 30 microns in width or one-third the width of a human hair. The team was able to vary the surface concentration of molecules on such short-length scale, thus enabling the use of this technique to achieve nanomanufacturing of devices.

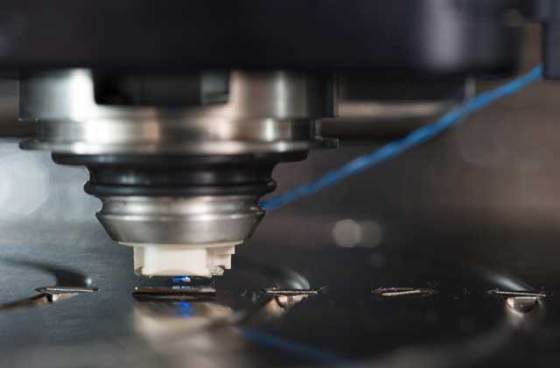

Production of chemical concentration gradients on the sub-micrometer scale is hardly achievable with existing techniques. Georgia Tech researchers produced chemical gradients of amine groups using an atomic force microscope and an approach called ThermoChemical NanoLithography (TCNL).

TCNL approach uses a heated cantilever to drive a localized nanoscale chemical reaction at an interface, where a reactant is transformed into a product. By varying the heat at each location, the research team controlled the number of new molecules that were created – the greater the heat, the greater the local concentration.

When more heat was applied the lighter shades of gray were produced, as seen on the Mini Lisa’s forehead and hands. Less heat produced the darker shades in Mini Lisa’s dress and hair that can be seen when the molecular canvas is visualized using fluorescent dye. Each pixel is spaced by 125 nanometers.

“By tuning the temperature, our team manipulated chemical reactions to yield variations in the molecular concentrations on the nanoscale. The spatial confinement of these reactions provides the precision required to generate complex chemical images like the Mini Lisa”, said Jennifer Curtis, an associate professor in the School of Physics at Georgia Tech.

According to the researchers, atomic force microscopes are fairly common and the thermal control is relatively straightforward. These features make the approach accessible to both academic and industrial laboratories. Even with a single cantilever, TCNL provides high spatial resolutions at a speed faster than other currently existing methods. In order to accelerate the pace of production devices with TCNL, the research team has recently integrated nanoarrays of five thermal cantilevers.

“We envision TCNL will be capable of patterning gradients of other physical or chemical properties, such as conductivity of graphene. This technique should enable a wide range of previously inaccessible experiments and applications in fields as diverse as nanoelectronics, optoelectronics and bioengineering”, said Curtis.

The Georgia Tech research team is hopeful that TCNL will enable nanoscale printing integrated with the fabrication of large quantities of surfaces, or everyday materials whose dimensions are more than one billion times larger than the TCNL features themselves.

For more information, read the paper published in the journal Langmuir: “Fabricating Nanoscale Chemical Gradients with ThermoChemical NanoLithography“.

Leave your response!