SLIPS as anti-ice and anti-frost coating for metal surfaces

A team of researchers from Harvard University devised a new way to combat ice and frost on various surfaces, including metal surfaces. Once coated, the surfaces quickly shed condensation droplets as well as frost simply by employing gravity. The technology could find its use as a coating for a wide variety of metal surfaces used in refrigeration systems, wind turbines, aircraft, marine vessels, and the construction industry.

A team of researchers from Harvard University devised a new way to combat ice and frost on various surfaces, including metal surfaces. Once coated, the surfaces quickly shed condensation droplets as well as frost simply by employing gravity. The technology could find its use as a coating for a wide variety of metal surfaces used in refrigeration systems, wind turbines, aircraft, marine vessels, and the construction industry.

Led by Joanna Aizenberg, Amy Smith Berylson Professor of Materials Science at the Harvard School of Engineering and Applied Sciences (SEAS) and a Core Faculty Member at the Wyss Institute for Biologically Inspired Engineering at Harvard, the group decided to use Slippery Liquid Infused Porous Surfaces (SLIPS) coating they developed earlier. However, applying SLIPS directly onto metal surfaces proved to be tricky.

As a solution, Aizenberg and her team developed another coating capable to stick to metal, thus enabling the SLIPS to adhere on its other side. The coating can be applied over a large scale and finely sculpted to lock in the lubricant fit metal surfaces of various shapes.

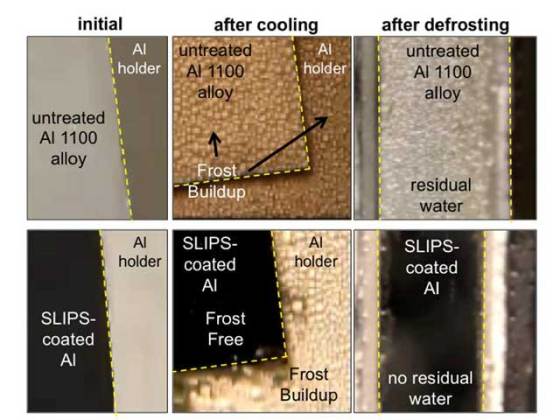

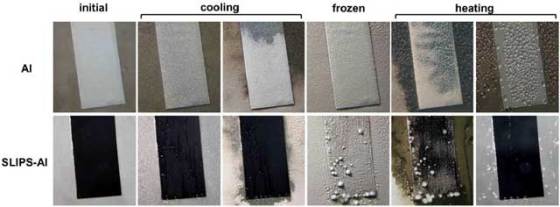

“Unlike lotus leaf-inspired icephobic surfaces, which fail under high humidity conditions, SLIPS-based icephobic materials, as our results suggest, can completely prevent ice formation at temperatures slightly below 0°C [32°F] while dramatically reducing ice accumulation and adhesion under deep freezing, frost-forming conditions”, said Aizenberg.

To demonstrate the robustness of the technology, Harvard researchers successfully applied it to refrigerator cooling fins and tested it under a prolonged, deep freeze condition. Compared to existing “frost-free” cooling systems, their innovation completely prevented frost far more efficiently and for a longer time.

In addition to allowing for the efficient removal of ice, the technology lowers the energy costs associated by several orders of magnitude. Thus, the readily scalable approach to slippery metallic surfaces holds great promise for broad application in the refrigeration and in other high-humidity environments where ice-repellant surfaces are desirable. All you need is to tilt or slightly agitate the surface, with forces as low as weaker winds or vibrations.

“This new approach to icephobic materials is a truly disruptive idea that offers a way to make a transformative impact on energy and safety costs associated with ice, and we are actively working with the refrigeration and aviation industries to bring it to market”, said Aizenberg.

For more information, read the paper published in the ACS Nano: “Liquid-Infused Nanostructured Surfaces with Extreme Anti-Ice and Anti-Frost Performance”.

When will SLIPS be available to the public Dave Chatham Ontario Canada.